Optimal quality inspection

in automation

Quality assurance is a crucial process step for all modern production systems. Availability and low pseudo-waste when checking qualitative requirements are highly significant here. Quality inspection systems are used for a wide variety of applications such as the production of single parts, the assembly of components as well as the inspection of finished products before packaging (end of line).

The processes for checking the presence of components, checking the correct mounting position or even checking whether or not parts are undamaged are all performed with high accuracy and availability guaranteed.

di-soric offers a wide-ranging portfolio of high-performance sensors based on various technologies with innovative interfaces, all of which offering you enhanced added value.

Application requirements

for the selection of the optimal sensor

- Type of inspection

- Component size

- Working distance

- Resolution

- Ambient light

- Cycle time

- Communication interface

- Check whether a feature is present

- Frequently checked features: Distance, edges, brightness or patterns

- Typical applications: Assembly check, counting objects

- Checking surfaces for changes or damage

- Typical applications: Checking interior and design elements, monitoring functional areas

- Checking dimensions, geometries and angles

- Typical applications: Diameter check, profile and position measurements

- Identification of a component by reading the ID code

- Typical applications: Track and trace, reading printed and directly marked codes

- Check whether the component present corresponds to the specification

- Frequently checked features: Color characteristics, ID code, design and component geometry

- The position check determines the position of a component

- Typical applications: Assembly check on manual workstation, feed control

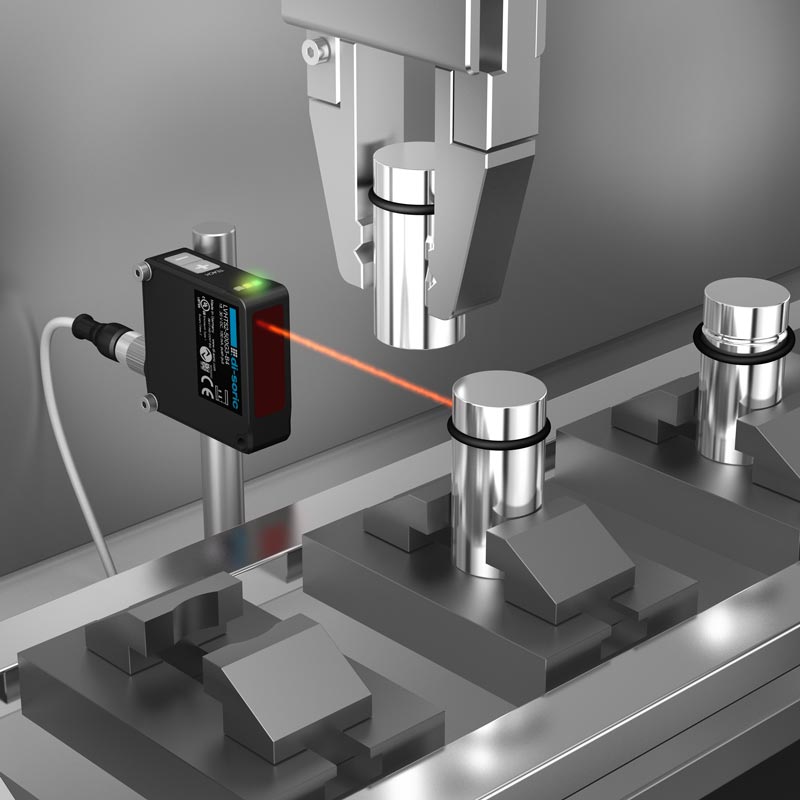

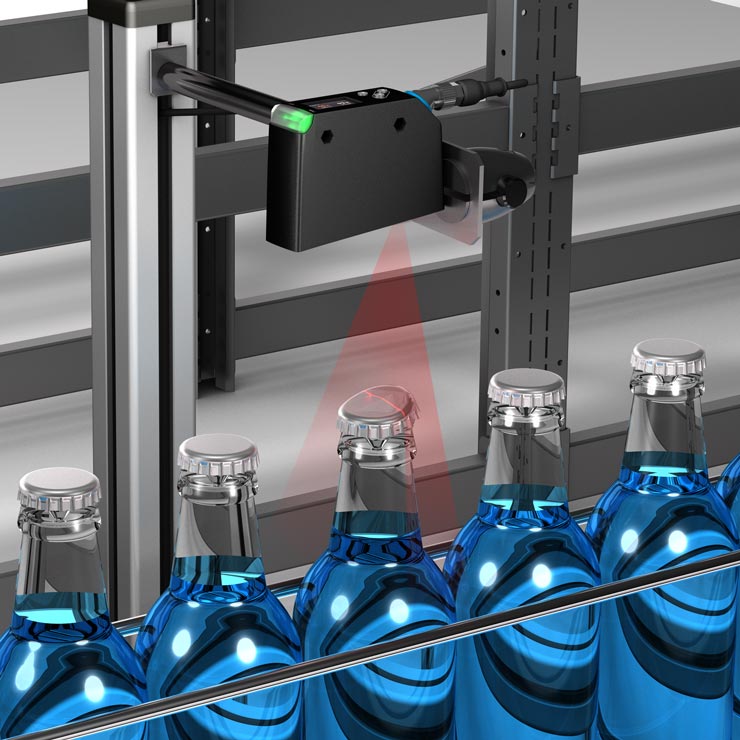

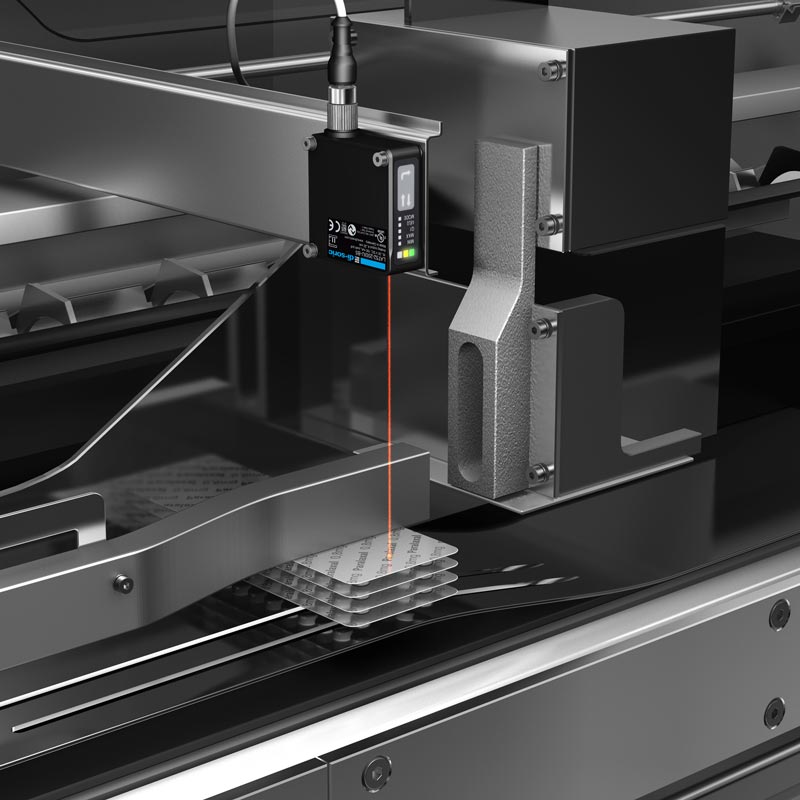

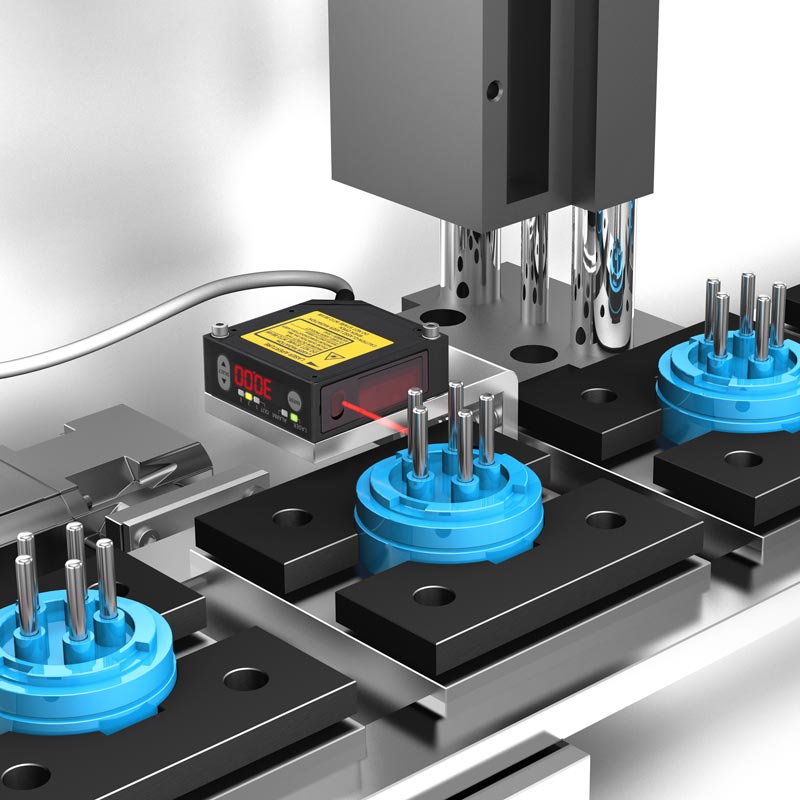

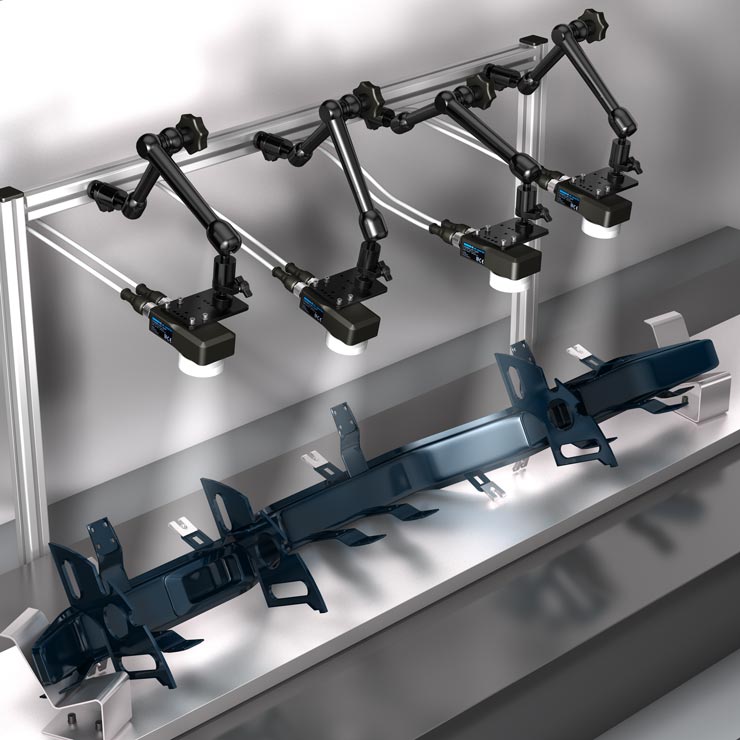

Presence

check

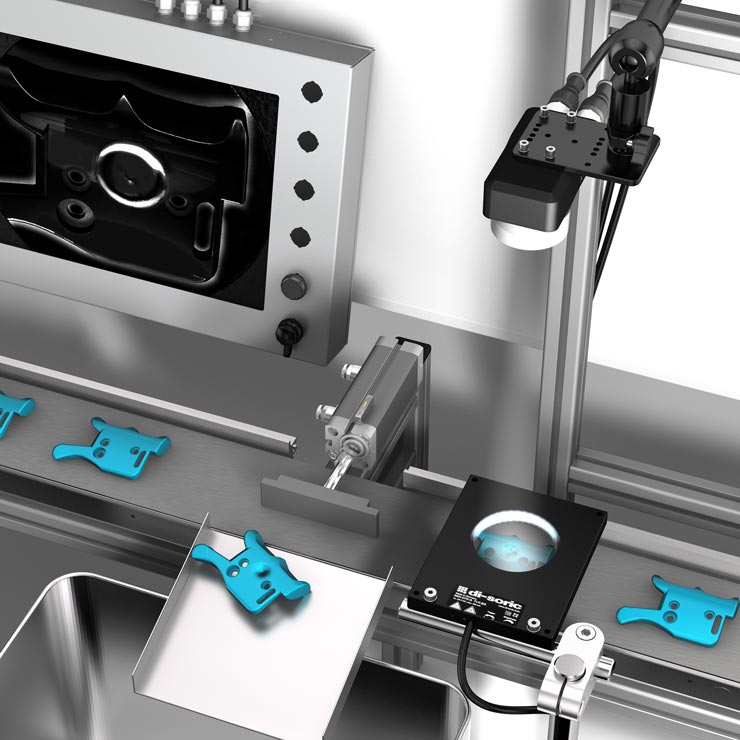

The presence check of components is a standard request for quality inspection in all industries. di-soric offers a portfolio of sensors with a wide variety of physical functional principles for a component presence check to always ensure secure processes. High ambient light immunity and reliable object detection are decisive in this situation.

Our external lighting, which can further optimize the process stability in many applications, round off our sensor portfolio.

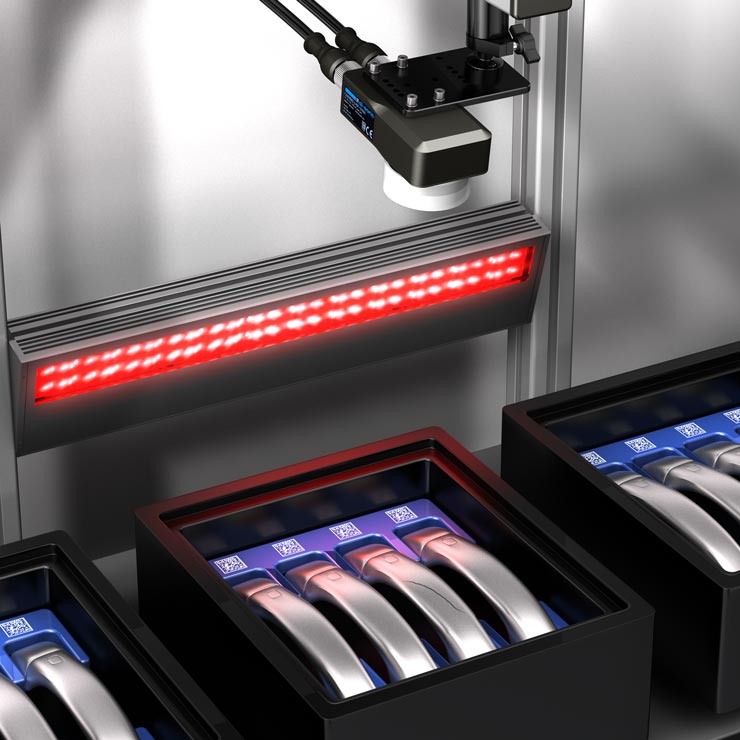

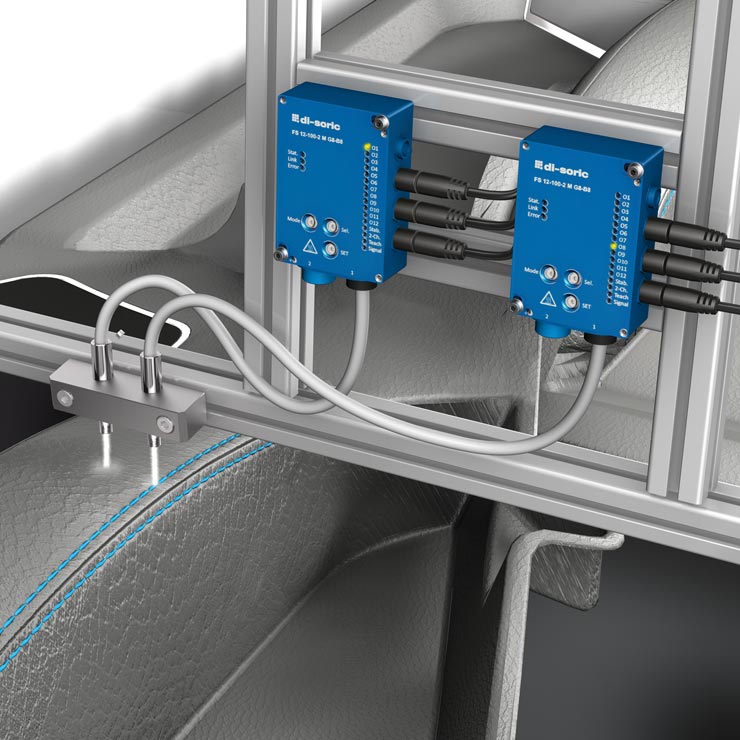

Surface

check

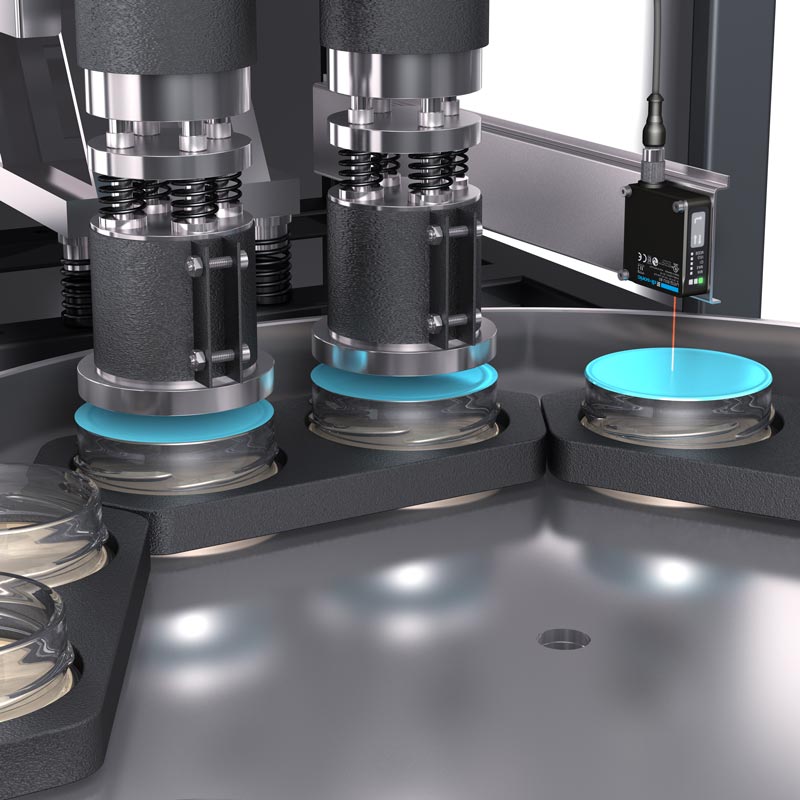

Surfaces are not only checked to safely detect damage such as scratches, cracks or deformations – design specifications must also be met and functional characteristics ensured.

In many of these situations, the right lighting setup is of vital importance. The di-soric portfolio offers the right solutions here for any type of application.

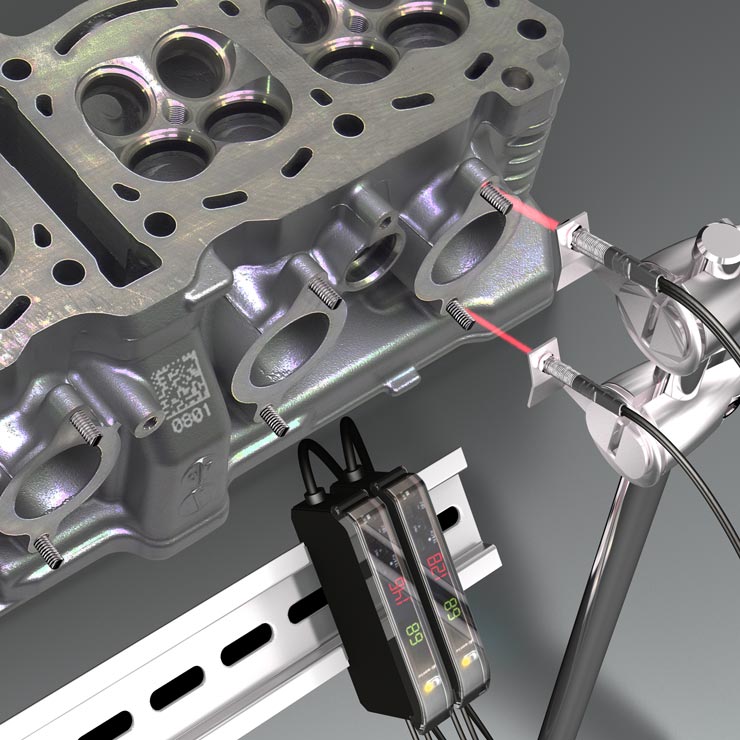

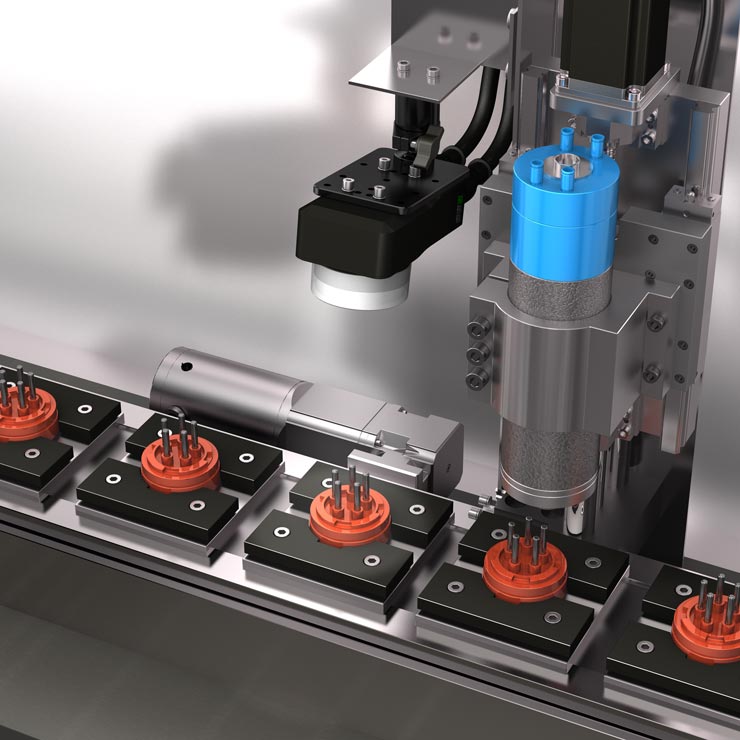

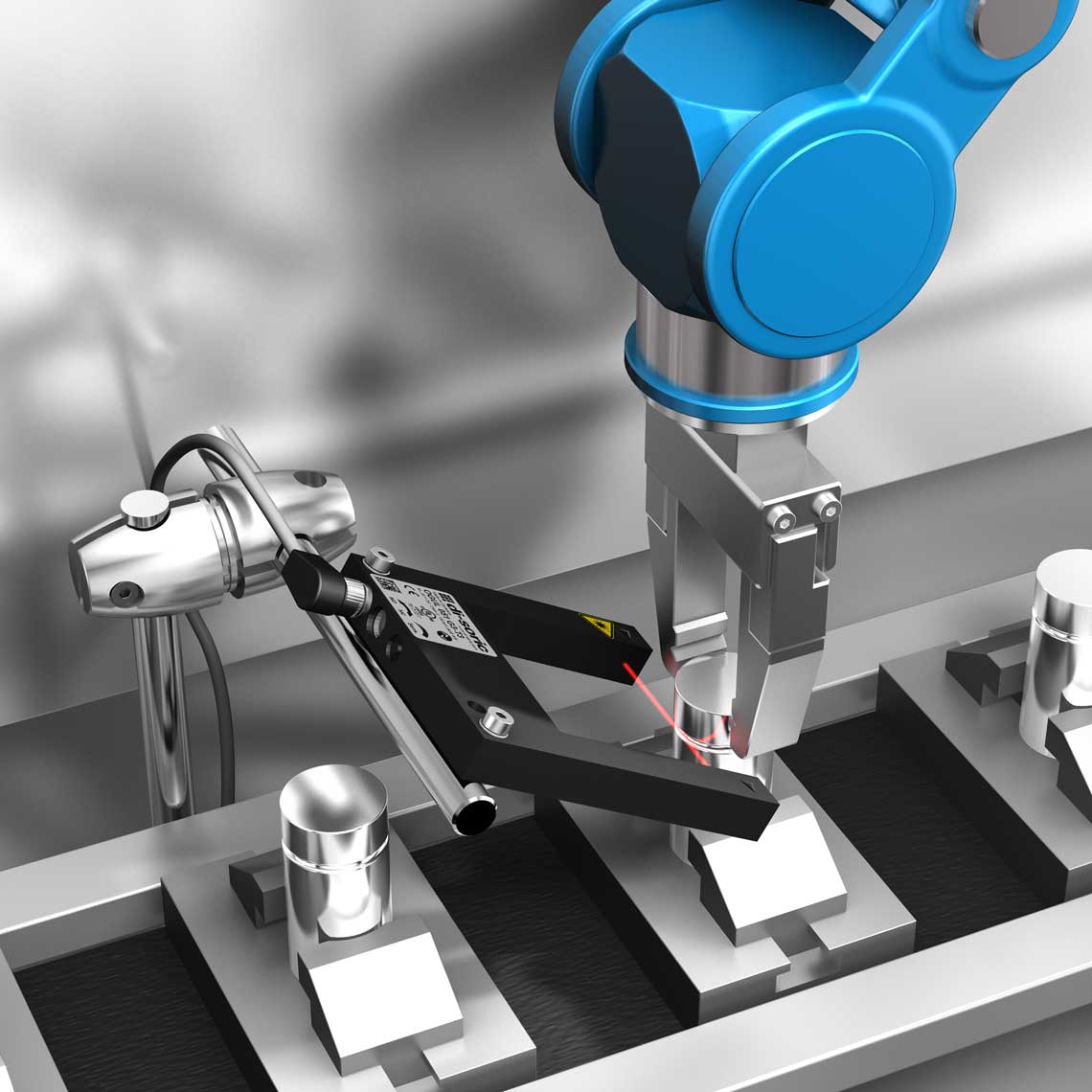

Size accuracy

check

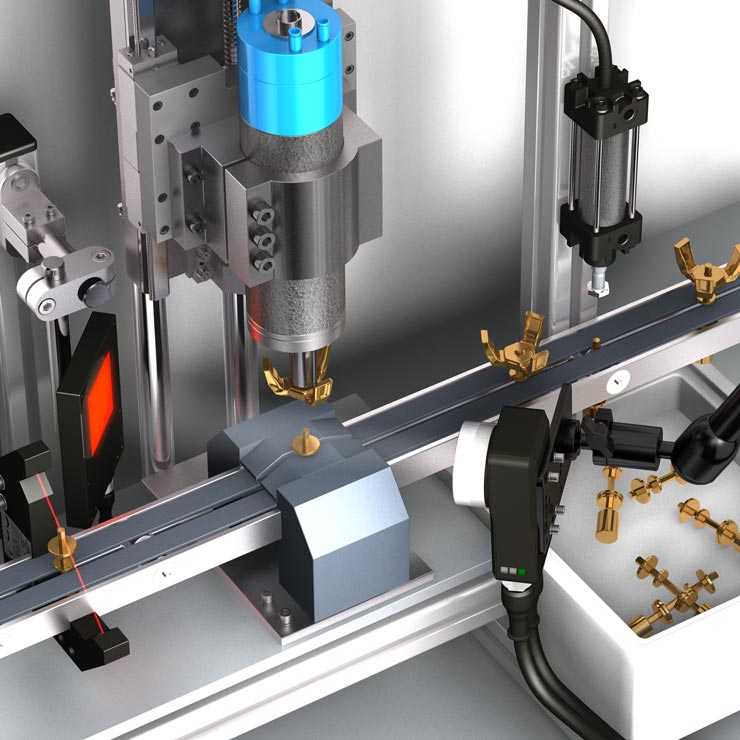

When joining components, it is important to check individual parts for size accuracy. This can be done in a manner that is comparative, relative as well as measuring.

di-soric has the right solutions in its portfolio for all requirements.

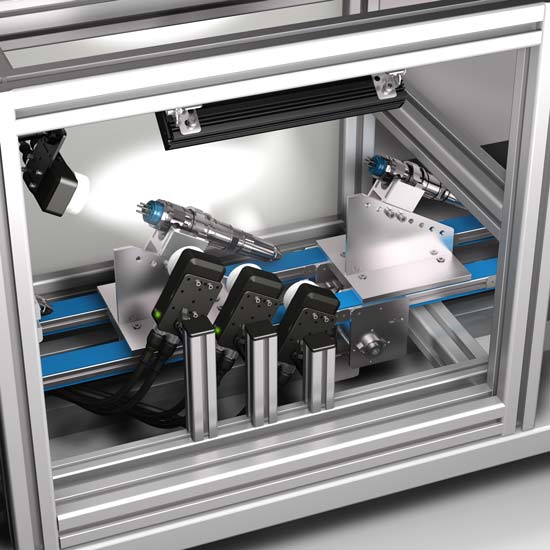

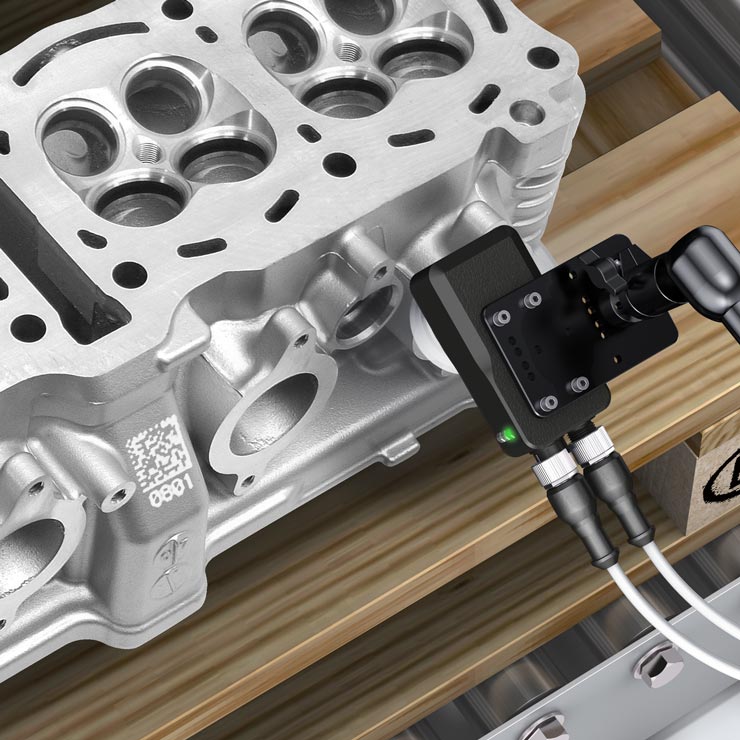

Type

identification

The tracking and tracing of parts is a central component of Industry 4.0. di-soric offers the right solutions to enable the reliable detection and further processing of contents for a wide variety of marking options, e.g. printed ID codes on labels or the direct marking on the component material (DPM).

Type

verification

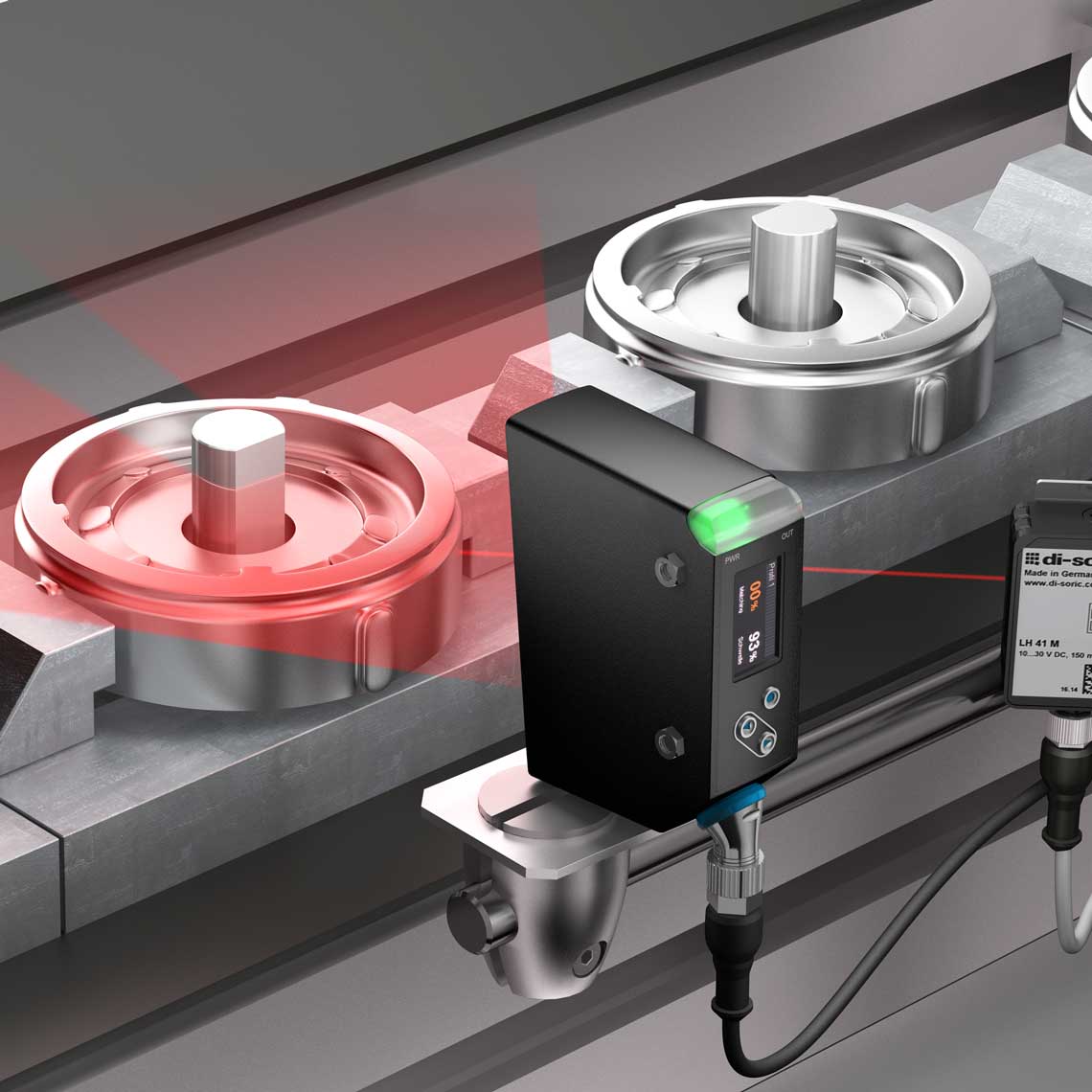

The verification of requirements such as component geometry, design and color is an essential part of quality assurance.

di-soric offers a wide-ranging portfolio of vision sensors, handheld ID readers, color sensors and trigger sensors to ensure a reliable result for each situation.

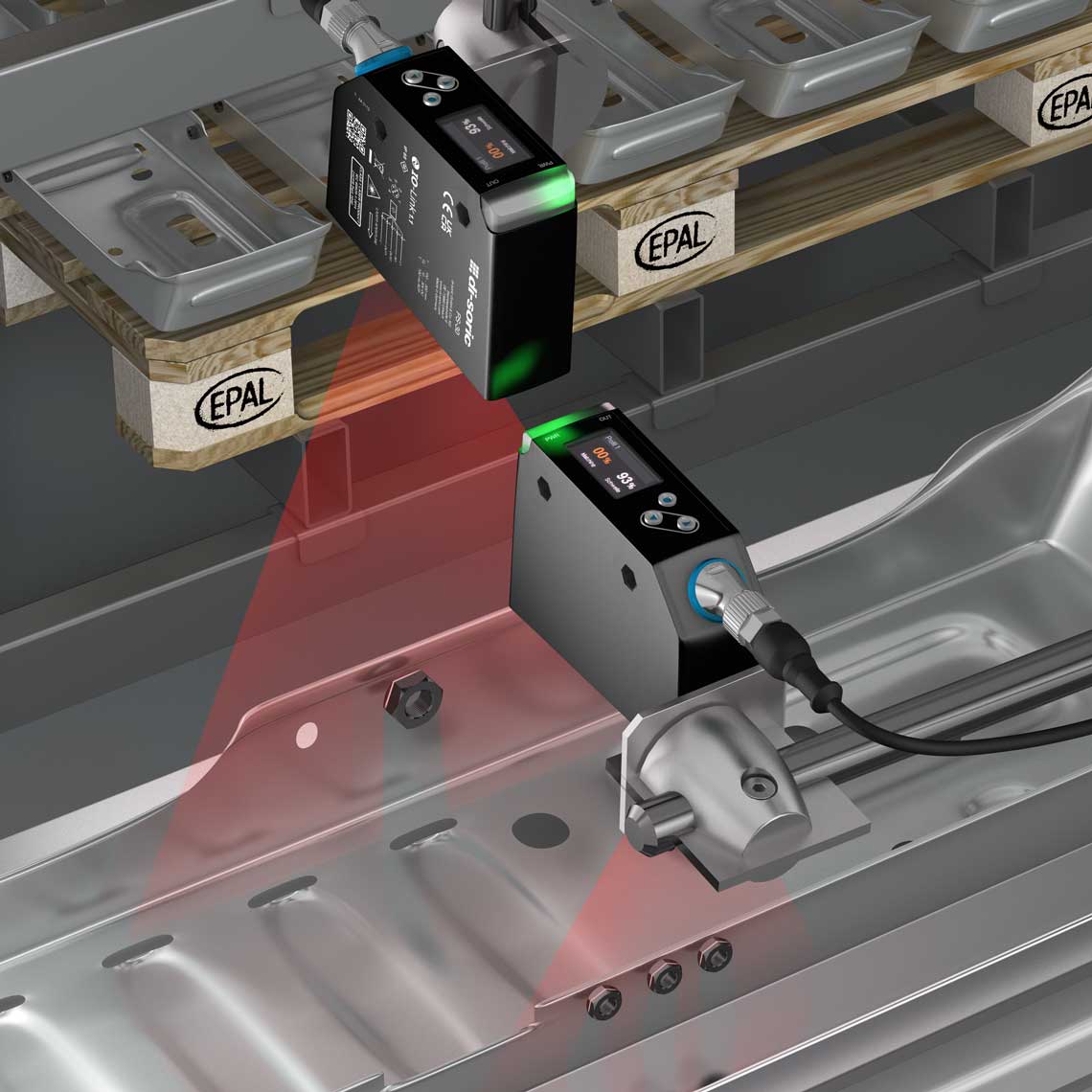

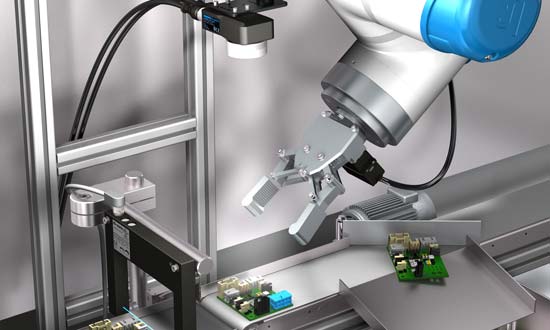

Position

check

Along with the location, the orientation of a single component as well as the position of a group of components or packaging can be detected.

di-soric has combined the numerous methods for this inspection into one product portfolio for quality inspection.

Sample order / Appointment

Download