Areas

Our areasof competence

The wide product range is rounded off by our flexibility for customer-specific solutions.

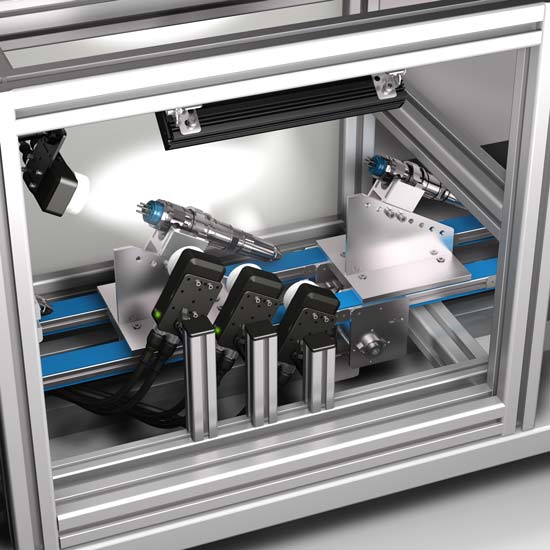

Quality assurance is a crucial process step for all modern production systems.

Quality inspection systems are used for a wide variety of applications such as the production of single parts, the assembly of components as well as the inspection of finished products before packaging (end of line). di-soric offers solutions based on various technologies with innovative interfaces, all of which offering you enhanced added value.

The essential characteristic of new production concepts is linking the information flow with the material flow. This enables the identification of the conveyor units at any time and at any location, ensuring versatile control at each production step.

A prerequisite is the reliable recognition of all common 1D and 2D codes by identification systems.

The essential characteristic of new production concepts is linking the information flow with the material flow. This enables the identification of the conveyor units at any time and at any location, ensuring versatile control at each production step.

A prerequisite is the reliable recognition of all common 1D and 2D codes by identification systems.

Optimal lighting in machines and systems is an important factor in industry for high productivity,as good visibility and clear signaling can reduce downtimes in the event of a malfunction. Good lighting conditions have a positive effect on the management of visual tasks, work performance and work quality, and ensure greater safety in the workplace.

The requirements for industrial lighting are so diverse that there is no universal, perfect solution for a single lighting that fits all industrial workstations, machines or lines. Lighting from di-soric is individually tailored to the specific characteristics and requirements of each need.

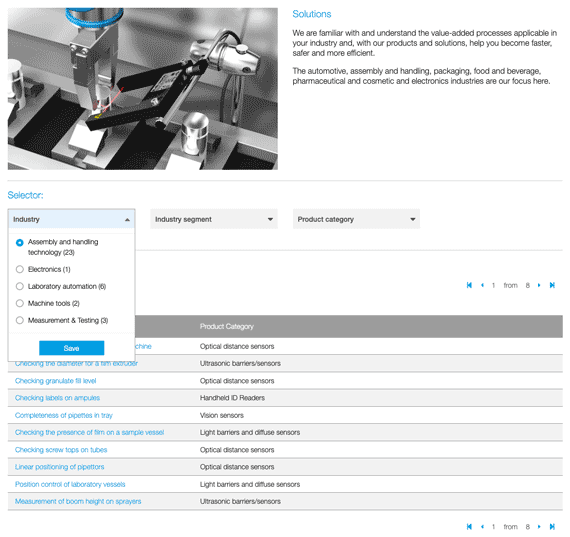

We are familiar with and understand the value-added processes applicable in your industry and we can help you become faster, safer and more efficient with our products and solutions.

Find solutions for your applications easily and quickly via our solutions selector.

We are familiar with and understand the value-added processes applicable in your industry and we can help you become faster, safer and more efficient with our products and solutions.

Find solutions for your applications easily and quickly via our solutions selector.