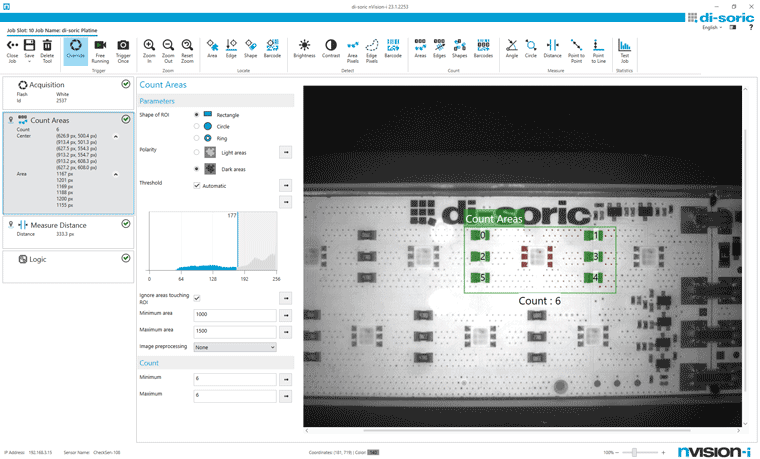

Clear, well-structured: the intuitive user interface of the nVision i-Software.

Modern image processing systems play a key role in process automation. For 2022, the VDMA forecasted an increase of 5% with sales of 3.2 billion euros for the industrial image processing industry in Germany. System manufacturers and integrators can select from a variety of powerful sensors, components and integrated overall Vision solutions. Current Vision sensors fulfill nearly all common requirements of industrial image processing applications. A sensor like the rugged and flexible CS-60 from di-soric has an integrated lighting concept and three M12 interchangeable lenses for use in a wide variety of detection, counting and quality inspection tasks.

Software often tips the scale in the selection of a certain overall Vision solution. Products on the market differ greatly here. nVision-i is a newly developed software that, in combination with the CS-60 Vision Sensor, ensures reliable, flexible and efficient industrial image processing solutions. With its graphical user interface, users can complete tasks without special Machine Vision knowledge and skills and get systems up and running quickly and smoothly. To do so, they select the required inspection tools, add them by dragging & dropping and configure them to their needs. The clear visualization of the pipeline and the ability to link individual tasks in the so-called logic tool offer a high degree of flexibility and speed in implementation.

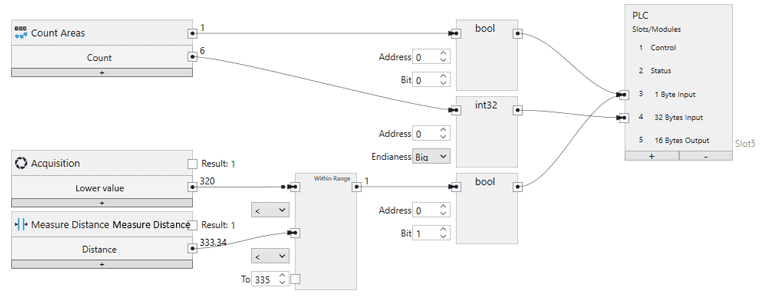

Graphical parameterization without programming knowledge in the logic tool, without stressing the PLC.

Specifically, an inspection task is implemented in defined jobs: Each job starts with an acquisition tool, where the image acquisition with lighting and input data is defined. A job ends with the logic tool, which prepares the results of individual tools and configures output data. In essence, nVision-i consists of two parts: nVision-i Runtime, which works in the CS-60 Vision Sensor, and nVision-i Designer, which is installed on the PC. Once a job is finished, it can be run automatically on the sensor; a computer connection is unnecessary.

The logic tool links results with outputs. The ability to freely link results from multiple tools into one overall result directly in the Vision Sensor using simple graphical configuration offers the user special advantages and maximum performance without PLC utilization. Communication with a machine is established via PROFINET, EtherNet/IP, TCP/IP or digital inputs and outputs. Images and inspection results can be saved permanently via FTP or SFTP for tracking purposes – an indispensable advantage for Industry 4.0 applications!

Depending on its complexity, a job consists of a sum of tools, which are collected and clearly structured into groups in the nVision-i software. For example, the Detection tool set includes tools such as brightness, contrast, areas, edge pixels, etc. The Localization tool set includes the area, edge, shape and barcode tools for determining the position and angle. Counting consists of the areas, edges and shapes tools. The Measurement tool set includes the angle, circle, distance, point-to-point and point-to-line tools. The precise, non-linear calibration tool makes measurements possible in millimeters instead of pixels.

nVision-i offers the necessary transparency and user-friendliness in every task step. In the clearly structured navigation menu, users find everything they need for their application. They select the tool they need from the menu catalog. The user interface shows help, status, measured values and test results permanently or on request. During configuration, users directly enter relevant search criteria as well as limit values for the evaluation criteria. For direct control and analysis, monitoring of images and measured values is also possible during operation. Furthermore, nVision-i offers a context-sensitive description of all tools.

If requirements change, users can download and add additional tools. A CS-60 Vision Sensor equipped with Localization, Detection and Counting can be expanded with additional functions such as Measurement and Reading 1D & 2D Codes via simple licensing. This takes just a few minutes, and users only pay for what they need. In the future, sensors will no longer need to be replaced due to changing application requirements. As desired, the look & feel of the user interface can be adapted to the design and corporate identity of the user's company.