Fast, reliable reading and identification of ID codes of virtually any type is a basic requirement for efficient operations and high productivity in numerous production, conveying and logistics processes. Modern identification systems are used in applications such as identifying and tracking components, products and packaging. In doing so, they link the flow of information with the flow of materials. Ideally, they detect the type and condition of the conveyed material at any time and at any desired location and can thus influence the corresponding production segment in a versatile and process-optimizing manner. Identification solutions such as the ID-600 fixed-mounted ID reader thus form the basis for highly automated production.

The ID reader in the rugged and compact IP67 housing is used in manufacturing companies in almost all industries. Strong algorithms ensure that all DPM codes are read, especially in the assembly & handling area. The IP67 protection class ensures that the ID-600 fixed-mounted ID reader works even in systems with high levels of dust, oil and dirt without any loss of performance.

Clearly arranged and simply understood, di-soric's nVision-i software is quick and easy to configure and provides users with a wide-ranging set of powerful code reading tools. It ensures the reading of common 1D, 2D and DPM codes as well as data transmission via various communication interfaces. The ID-600 ID reader is suitable for capturing barcodes in the context of secondary packaging, among other things, and recognizes a wide variety of DataMatrix and QR codes. It can read multiple codes simultaneously, ensures reliable tracking of consumer goods, and masters a wide range of quality inspection tasks. The versatile ID reader meets all application requirements, for example when tracking components with directly marked codes, involving the need to transfer both decoded data as well as the created images via FTP/SFTP protocol for quality control.

The ID-600 captures even the smallest codes with low contrast under borderline lighting conditions or in environments with active washing. Four M12 interchangeable lenses with different focal lengths combine with the integrated, switchable dual-color LED high-power illumination to deliver high-quality images with distance, field of view and resolution in mind. This also applies to high travel speeds, large working distances and under changing requirements. With a wide range of external lighting, di-soric offers the right setup for any desired application.

The image correction integrated in the course of code reading is a plus for the user. On the software side, distortions and shadowing at the image edge can be easily eliminated through calibration. In particular, the ID reader meets the requirements in those areas where flexibility, easy configurability and fast changeovers are paramount.

Because it is plug-and-play, almost anyone can quickly implement and commission the ID-600 quickly thanks to the easy-to-use nVision-i operating software developed by di-soric. Users select their desired inspection tools from a graphic user interface and apply them by dragging and dropping. The navigation menu (available in German, English, French, Italian, Spanish, Chinese and Korean) displays all tools, including a context-sensitive description that can be displayed, clearly arranged in groups on the right-hand side.

The user interface can be used to identify all code types automatically and set the parameters for search criteria directly and easily. The operating personnel can call up measured values and test and status results at any time or view images for the purpose of control and analysis, even during operation. The clear visualization of the pipeline and the ability to link individual tasks in the logic tool offer users a high degree of transparency and flexibility in implementing the desired application.

The selected tools can be quickly adapted to changed production parameters as needed, individually optimized through customization, and expanded at any time via software upgrades. This gives users the assurance that the ID-600 ID reader is always up to date in terms of performance and meets the required quality and productivity standards. The ID-600 fixed-mounted ID reader and the nVision-i operating software from di-soric support the Digital I/O, TCP/IP, Profinet, HTTP, FTP/SFTP and ReST-API industrial protocols.

Customized optical, electronic and mechanical accessories complete the range in the identification sector.

Images:

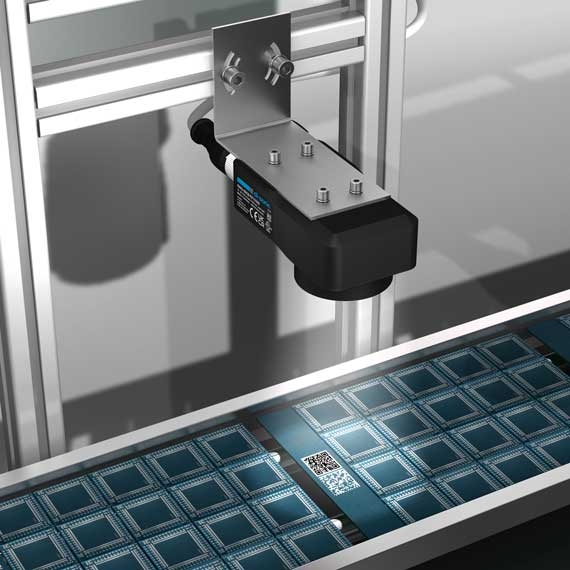

Image 1: The ID-600 fixed-mounted ID reader from di-soric recognizes common 1D, 2D as well as DPM codes even at long distances and under adverse ambient conditions.

Image 2: ID-600 ID reader from di-soric: Quality inspection and capture of the barcode as part of

secondary packaging.

Image 3: ID-600 ID reader from di-soric: Quality inspection and capture of DataMatrix and QR codes in the feed.